Innovative Virtual Reality Experiments in Civil Engineering by Asfan Company

Asfan Company has always been at the forefront of integrating cutting-edge technology into civil engineering. The recent introduction of virtual reality (VR) experiments is a testament to their commitment to innovation and excellence. These VR experiments are designed to simulate real-world scenarios, providing engineers, researchers, and students with immersive and interactive experiences that closely mimic the complexities of actual civil engineering projects. This article delves into three specific experimental areas developed by Asfan Company: the Asphalt Test, the Rotation Test, and the Concrete Test.

1. Asphalt Test:

Paving the Way for Superior Road Infrastructure

The Asphalt Test is a critical component of Asfan Company's VR experiments, focusing on the behavior of asphalt under various conditions. Asphalt is a widely used material in road construction, and understanding its properties is essential for ensuring durable and safe road infrastructure.

Virtual Reality Simulation

The VR simulation for the Asphalt Test allows users to explore the effects of different temperatures, loads, and environmental conditions on asphalt. By adjusting these variables, users can observe how asphalt behaves under various stress levels, how cracks form, and how the material's lifespan is affected. The simulation also includes scenarios where users can experiment with different asphalt mixtures and additives to improve performance.

Applications in Real-World Engineering

This VR experiment is invaluable for civil engineers involved in road construction and

maintenance. It enables them to predict potential issues before they arise and to design more resilient road

surfaces. Furthermore, the VR environment allows for the safe and cost-effective testing of new materials

and techniques, reducing the need for physical prototypes.

Please visit the page

2. Gyratory Test:

Enhancing Precision through VR

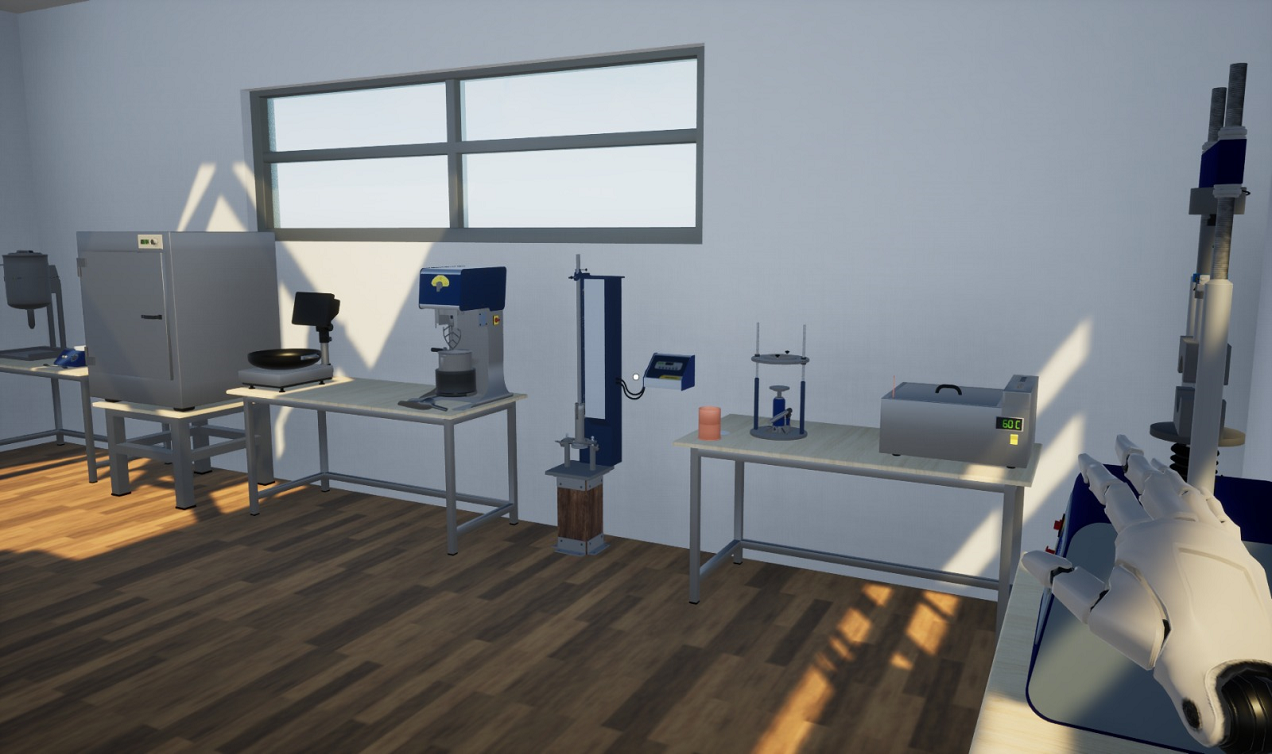

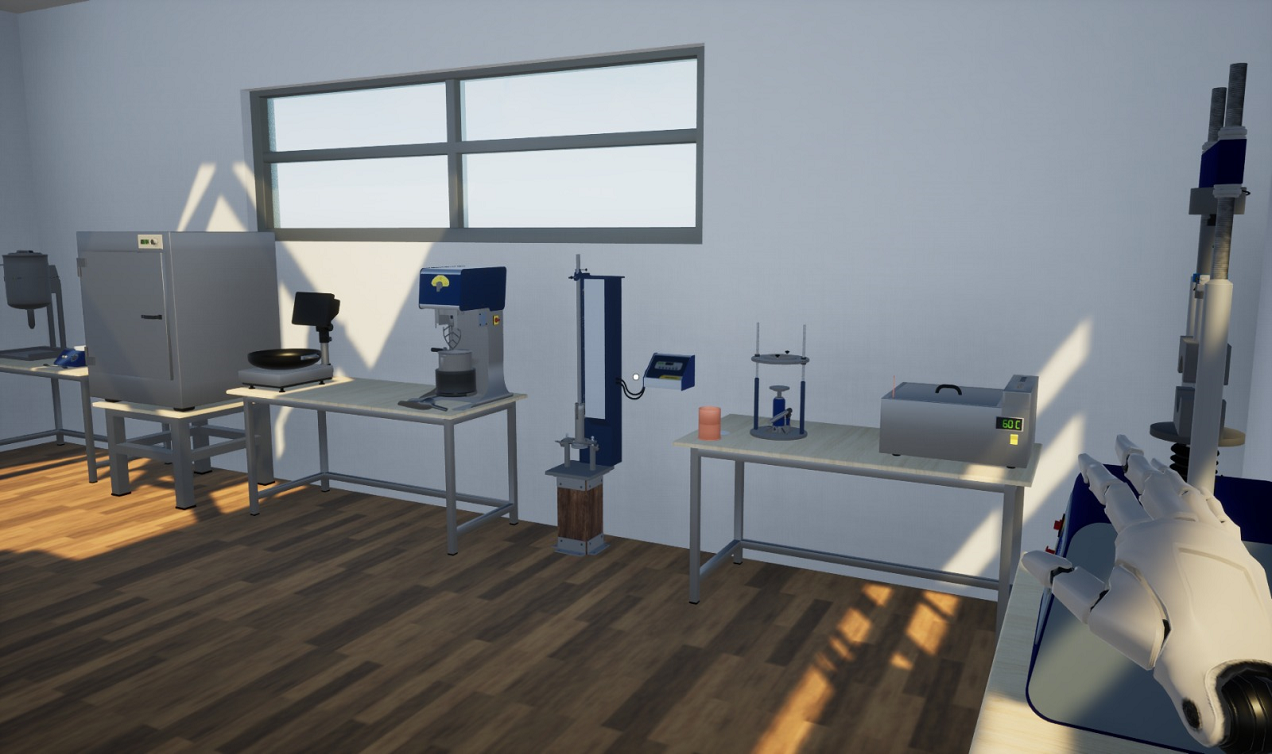

The Gyratory Test is another vital procedure in civil engineering to evaluate the compaction properties of asphalt mixtures. This test helps determine the mixture's density and ability to withstand traffic loads over time. Asfan company's VR experiment takes this test into the virtual realm, providing an interactive and highly accurate simulation.

Specifications of the Virtual Gyratory Testing Area

Realistic Gyratory Compactor: The VR environment includes a highly detailed simulation of

the gyratory compactor, a device used to simulate the compaction process that occurs during road

construction.

Dynamic Interaction: Users can adjust the gyratory angle, pressure, and number of gyrations to study

their impact on the mixture. The virtual compactor responds in real time, allowing engineers to experiment

with different settings.

Visualization of Compaction Process: The VR system provides a visual representation of the compaction

process, showing how the asphalt mixture densifies with each gyration. This visualization helps engineers

understand the relationship between compaction and material properties.

Performance Prediction: The VR platform can predict the long-term performance of the asphalt mixture

based on the results of the Gyratory Test. This feature is particularly useful for designing durable

pavements.

Please visit the page

3. Concrete Test:

Ensuring the Durability of Construction Materials

Concrete is one of the most commonly used materials in construction, and its durability is paramount to the success of any project. The Concrete Test in Asfan Company's VR experiments is designed to simulate various scenarios that concrete structures might face during their lifespan.

Virtual Reality Simulation

The Concrete Test VR simulation allows users to experiment with different concrete mixtures and curing processes. Users can simulate the effects of temperature changes, moisture levels, and loading conditions on concrete, observing how these factors influence the material's strength and durability. The simulation also includes tests for crack propagation and the effects of different reinforcement strategies.

Applications in Real-World Engineering

This VR experiment is an essential tool for civil engineers and material scientists. It

provides a deeper understanding of how concrete behaves under different conditions, enabling the development

of more durable and resilient structures. The ability to test various mixtures and reinforcement strategies

in a virtual environment also accelerates the research and development process, leading to faster

implementation of innovative solutions in the field.

Please visit the page

Conclusion:

The Future of Civil Engineering with Virtual Reality

Asfan Company's virtual reality experiments represent a significant advancement in the field of civil engineering. By providing a realistic and interactive platform for testing and analysis, these VR experiments enable engineers to make more informed decisions, improve the quality of their designs, and reduce the risk of costly errors. The Asphalt Test, Rotation Test, and Concrete Test are just the beginning, as Asfan Company continues to explore new ways to integrate VR technology into civil engineering, paving the way for a future where innovation and excellence go hand in hand.

Explore More Projects

We welcome your questions, do not hesitate to contact us

- Create virtual reality and augmented reality experiences at the best prices

- Equipping engineering laboratories with the best equipment

- Virtual tours with 360° technology and also feature that you can see them through just one link

- Create virtual reality and augmented reality experiences at the best prices

- Equipping engineering laboratories with the best equipment

-

Virtual tours with 360° technology and also feature that you can see

them through just one link