Virtual Reality in Mechanical Works

Virtual Reality / Vocational Training

In the rapidly evolving world of technology, traditional training methods are being complemented and, in some cases, replaced by innovative solutions. One such breakthrough is the integration of virtual reality (VR) into mechanical works training. This cutting-edge approach offers unprecedented opportunities for learning and skill development in mechanical engineering, manufacturing, and maintenance industries.

The Benefits of VR in Mechanical Works

- Hands-On Experience Without Risks

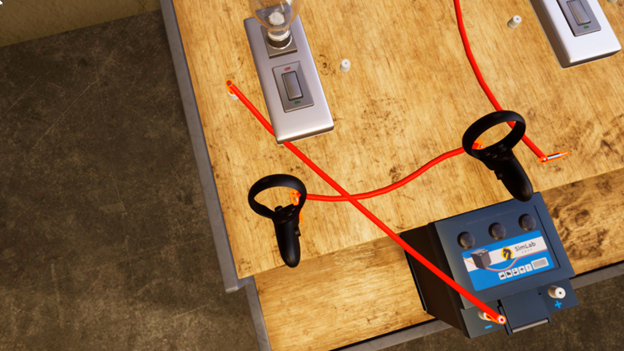

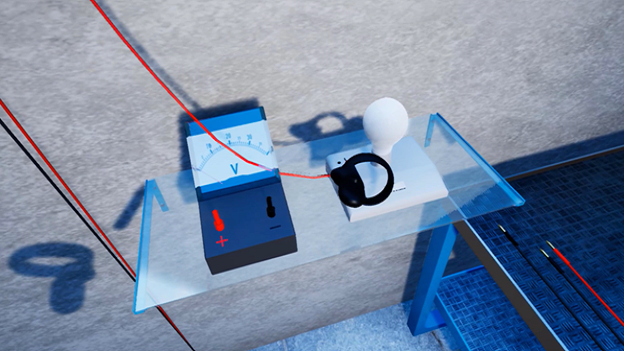

VR environments allow trainees to engage with mechanical machinery and components in a simulated setting. This hands-on experience helps them familiarize themselves with tools, techniques, and machinery without the associated risks of working with real equipment. Trainees can make mistakes, practice disassembly and assembly, and learn from their errors in a safe space.

- Enhanced Visualization and Understanding

Mechanical systems can often be complex and difficult to visualize. VR provides an immersive 3D experience that helps trainees understand spatial relationships and the functioning of various components. By seeing how parts interact within a system, learners can grasp concepts more easily than traditional textbooks or 2D diagrams allow.

- Immediate Feedback and Skill Assessment

One of the most powerful features of VR training is the ability to receive real-time feedback. As trainees work through simulations, the system can evaluate their actions, highlight mistakes, and suggest improvements. This immediate assessment not only enhances learning but also allows trainers to tailor the training experience to meet each learner’s needs.

- Cost-Effectiveness and Resource Efficiency

Traditional mechanical training often requires substantial resources, including physical materials and equipment. VR training eliminates much of these costs by allowing multiple simulations to occur without any physical wear and tear. Additionally, organizations can utilize VR to conduct training sessions with remote employees, minimizing travel and downtime.

Real-World Applications

The implementation of VR in mechanical works is already making waves across various industries. For instance, manufacturing companies are using VR simulations to train employees on machine operations, safety procedures, and maintenance tasks. Automotive sectors are employing VR for assembly line training, allowing new employees to grasp complex assembly processes before ever touching the actual vehicles.

Conclusion

As virtual reality continues to evolve, its applications in mechanical works training will expand even further. By providing safe, immersive, and effective learning environments, VR not only enhances the skills of current workers but also prepares the next generation of mechanical engineers and technicians for the challenges of tomorrow. The future of mechanical works training is not just on the shop floor; it’s in the virtual landscape, where possibilities are endless, and learning knows no bounds.

Call us

Whether you're an educator, an industry leader, or a trainee, consider exploring the opportunities that VR offers in mechanical works training. Embrace the future and transform the way you learn and teach in this dynamic field!

Explore More Projects

We welcome your questions, do not hesitate to contact us

- Create virtual reality and augmented reality experiences at the best prices

- Equipping engineering laboratories with the best equipment

- Virtual tours with 360° technology and also feature that you can see them through just one link

- Create virtual reality and augmented reality experiences at the best prices

- Equipping engineering laboratories with the best equipment

-

Virtual tours with 360° technology and also feature that you can see

them through just one link